The proper selection of Scaffold Planks goes a long way in safety maintenance, good durability, and increasing of productivity at any construction site. If you are up to a big-scale commercial project or a mere small renovation task, planks that fulfill the industry standards will definitely be of great help to the scaffolding system’s safety and stability. Having the correct knowledge is like safety-wearing, cost-saving, and time-saving all in one for contractors and builders throughout the entire project.

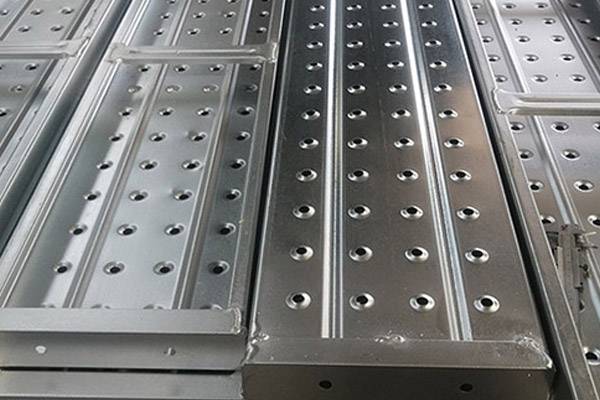

Material quality is the very first thing you should think of when choosing plank products. The safety of the workers and the ability of the structure to carry the load depend on the strength, the thickness, and the general solidity of the planks. Products made from pre-galvanized or high-grade hot rolled materials will be the most durable ones because the said materials resist corrosion and remain stable even under heavy-use situations. While you are checking the material quality of these planks make sure that they meet the safety standards and are strong enough to carry the normal loads in your construction site.

Each project comes with different load specifications and in your planks selection, these requirements should be taken into account. Before buying, check out the load-bearing specifications of planks so that they can be utilized for tools, workers, and construction materials. The load capacity should be aligned with project requirements, mainly in the case of multi-level or heavy-duty settings. High-quality planks lead to the lowering of accidents, better safety, and more job site productivity.

Hard and corrosive-resistant parts of a scaffold will manage to maintain their performance for a long time without being replaced frequently. That is because construction sites are usually the origin of various severities such as moisture, dust, temperature changes, and even chemicals. Besides, galvanized steel planks are mostly preferred for their resistance to rust and for their ability to keep the structural integrity for a long time, that is what makes them the right choice for the outdoor as well as for the long-term projects.

The design of the plank is very instrumental in the safety of the user. Features such as anti-slip surfaces, equal width, precise size, and accurate edges reduce greatly the risk of slips coming from the installation of the planks and also the risk of installation errors. Moreover, good-quality planks provide more friction to users' hands, even if the working condition is hard. Try to purchase products that have gone through safety and stability tests. Besides, good locking compatibility with other scaffolding components is what leads to an overall safer system.

Construction projects are different and so they demand planks of different lengths, widths, and thicknesses. The right choice of dimensions removes the problem of work safety and makes the work more comfortable. For instance, shorter planks are a good fit for small areas whereas longer planks give a chance for smoother movement in wider areas. Make sure, the plank sizes are the same as those of your scaffolding so that the installation can be perfect and the weight can be evenly distributed.

The efficiency of a good scaffolding system is not only dependent on planks but also on how well they work together with different accessories. For example, a Scaffolding Clamp is a component that must be compatible with the planks in order to have a setup that is both secure and safe. When the components don’t match, the safety of the workers may be in danger and there is a possibility of detachment or imbalance occurring accidentally during the construction activities. Being sure that planks and accessories are compatible keeps the structure stable and makes the working environment efficient.

The feature that makes the whole scaffold stable is the support system. It is only one factor that is very important to make sure that the planks are in harmony with the Scaffolding Verticals provided by Winntus Formwork Private Limited especially when it is a multi-level work that is going on. The right connection between the planks and the verticals results in support alignment that is more effective, less movement, and more safety being provided to the workers operating at various heights. Good vertical-plank compatibility is an absolute necessity to achieve a strong and safe construction framework.

The time factor is very important on the job sites and this is why it is necessary to have planks that are not heavy thus implying easy handling and at the same time strong enough to carry out demanding applications. With planks that are easy to put on, the labor hours are less, the project progress is faster, and the fatigue is decreased. Deciding on planks that can be rapidly set up and dismantled will, in fact, be a great site productivity enhancer.

Good manufacturers guarantee the same quality and the observance of the safety requirements all through. Suppliers whom you can trust give you the confidence that you are putting your money on durable and performance planks. Get in touch with a company that has a good reputation within the industry, is open about its quality control, and has many satisfied customers. It is a guarantee that the planks you will select will be able to perform the tasks that your project requires.

The right planks are what give the guarantee of safety, durability, and working efficiency in construction environments. By assessing material quality, load capacity, design, compatibility, and supplier reliability, you are in a position to make a well-informed decision which is a great support to the success of your project. Such planks do not only make work safer but also increase efficiency and have a long-lasting value which, in turn, makes them a must-have for every construction professional.

The integrity of any major construction site depen...

The construction world is moving away from the slo...

In a relatively short amount of time, Aluminium Fo...

The�...

Every...

Safety is the backbone of every successful project...

An immaculate concrete surface starts its journey ...

When it comes to construction and fabrication proj...

Construction and maintenance at heights are fraugh...

Construction sites are busy, high-risk environment...

The construction industry thrives on time and safe...

Modern construction sites, especially those that d...

Construction has historically grappled with costs ...

In construction, refurbishments, and major repairs...

The stability of every scaffold structure solves t...

In the fast paced modern construction world, contr...

In a metropolitan city like Gurgaon, where constru...

Scaffolding is one of the most basic and indispens...

Construction cost management is very important for...

A reassessment of formwork reveals its vital role ...

The building business is always updating, with nov...

The construction industry requires the right formw...

The construction industry is dynamic and ever-chan...

Scaffolding accessories are essential components i...

Scaffolding forms the very base of any constructio...

Maintenance is an important factor in quality assu...

Construction projects require robust and reliable ...

In the construction industry selecting the right m...

In the fast-paced world of construction, sustainab...

In the modern era, there are multiple methods and ...

Scaffolding is a term usually used for the scaffol...

The construction sites involve multiple works and ...