Fill out form below and we will contact you in 10 minutes

Discover why our formwork solutions stand out. From unmatched quality and durability to personalized customer service, we prioritize excellence. Trust us for reliable, innovative, and cost-effective formwork solutions tailored to your needs.

Discover premium raw materials sourced globally for top-notch formwork solutions. From high-grade steel to advanced components, rely on Winntus Formwork Private Limited for excellence.

Experience precision fabrication at Winntus Formwork Private Limited Our state-of-the-art facilities ensure top-notch quality, reliability, and timely delivery for all your formwork needs.

Embrace unmatched precision in every project with our advanced technology and skilled team. Trust us to deliver precise formwork solutions consistently.

Unlock efficiency and reliability through standardized solutions. Our commitment to industry standards ensures seamless integration and consistent performance for your projects.

The main function of aluminium formwork is to provide a robust and erected position of the concrete solution in India. The formwork is used for setting up the layout cement in the reinforcing walls or...

Read More

We all know that Aluminium Formwork Accessories on Rent are essential components of the formwork system used in construction. If you are searching for the finest pieces of construction, contact us and...

Read More

Aluminium forwork is known as one of the most robust solutions for reinforcing the concrete structure in the building or construction sites in India. There are several benefits of aluminium formwork ...

Read More

Embrace cutting-edge construction technology in India with Winntus Formwork Private Limited.'s Aluminum Vertical Formwork. Our Aluminum Vertical Formwork in India offers a plethora of innovative ...

Read More

Embark on a new era of construction efficiency in India with Winntus Formwork Private Limited.'s Monolithic Formwork System. Our innovative Monolithic Formwork System in India revolutionizes the ...

Read More

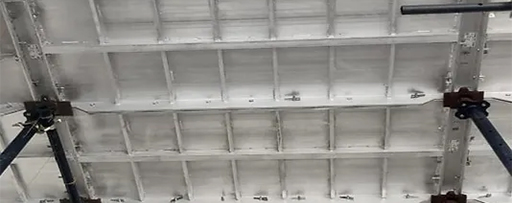

Unlock the potential of your construction projects in India with Winntus Formwork Private Limited.'s innovative Formwork. Our cutting-edge Aluminium Deck Panel Formwork in India boasts a plethora...

Read More

|

Difference Between Aluminium formwork and conventional Method

|

|

| Aluminium Formwork | Conventional Method |

|

|